Services

What We Do

Our key services include defect identification and elimination, equipment repair and overhaul, accurate installations and condition monitoring for equipment fitness.

Specialized Asset Care Management & Maintenance

we specialize in delivering highly tailored Asset Care Management and Maintenance services aiming to ensure our clients maximize the full life cycle of their equipment.

Root Cause Analysis (RCA)

In the event of equipment failure, we conduct RCA to learn from the failure and implement preventive measures. This iterative process strengthens our continuous improvement cycle, enhancing equipment reliability and longevity.

Precision Maintenance & Aggressive Monitoring Strategies

Our commitment extends to performing precision maintenance during installations, overhauls, and repairs. Considering failure modes and consequences, we develop aggressive monitoring strategies to proactively prevent equipment failures, ensuring optimal performance.

Asset Management RCM Approach

We have adopted a very simple Asset Management RCM approach in which we engage in plant walkabouts to proactively identify and eliminate potential hazards. This comprehensive strategy involves developing tactics for high-risk equipment based on criticality and failure mode.

Strategic Business Risk Assessments

We conduct business risk assessments in all equipment's and zoom into all critical and problematic equipment's by applying strategic approach to minimize and resolve all issues.

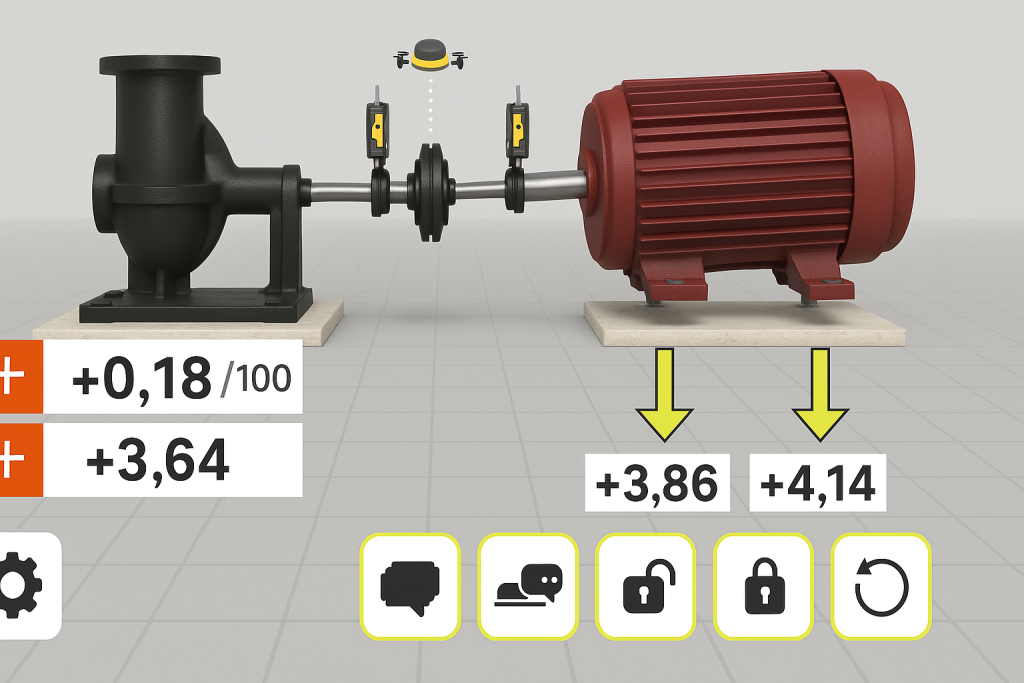

Triaxial Vibration Sensors

We utilize triaxial vibration sensors with integrated temperature measurements, transmitting data to the cloud for online monitoring or to a local database for field analysis. The sensors offer up to 12,800 lines of resolution for in-depth data analysis. Additionally, we provide wireless infrared thermography for electrical and mechanical equipment. Designed for durability, our sensors optimize battery life, withstand sun and rain exposure (IP67 certified), and send alerts when machines exceed configured thresholds.

Vibration Analyser Measures

Vibration Analyser measures, diagnoses and stores data about the vibrations produced by machinery.

Infrared Thermography Measures

Infrared Thermography measures, diagnoses and stores data about the temperature produced by machinery.

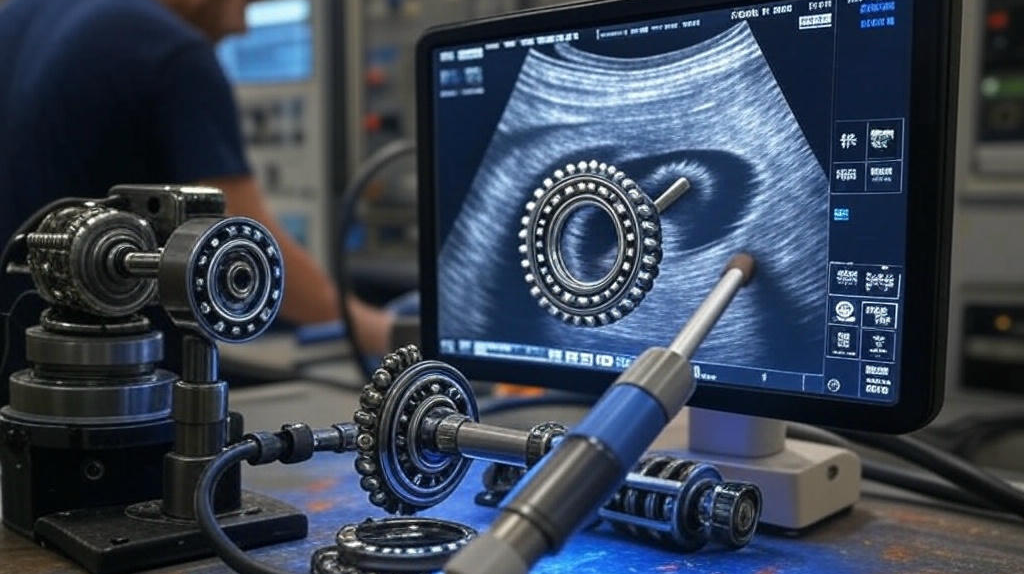

Ultrasound Monitors Electrical & Mechanical Bearings

Ultrasound monitors electrical & mechanical bearings to optimize the amount of grease needed to reduce friction and wear.

Hydrocarbon Management

Oil analysis provides vital information about machinery conditions without the need for disassembly or cutting, offering a non-intrusive method for comprehensive diagnostics.

Precision Maintenance: In-situ Balancing

In-situ Balancing of single or double impellor for up to 16 blades.

Precision Maintenance: Wireless

Wireless Precision Laser Alignment System

Non-Destructive Testing (NDT)

NDT is a technique for evaluating material properties and identifying defects or discontinuities in a component without causing damage to the original part. Online Infrared Thermography for substations, electrical cabin continuous monitoring

Online Monitoring System & RCA

Online Condition Monitoring continuously monitors machines and production processes, also functioning as a protective system. Root cause analysis (RCA) is employed to learn from failures and develop proactive strategies to prevent their recurrence.

Ready to Maximize Your Equipment’s Performance?

Partner with CCMS (Pty) Ltd for expert asset management and maintenance solutions. Let’s work together to extend the life of your equipment and drive operational excellence.